80/20 Standard Builds

This document will cover the standard ways to build with 80/20 for FRC prototyping. Following these standards will make it easier and faster to build and iterate on your designs.

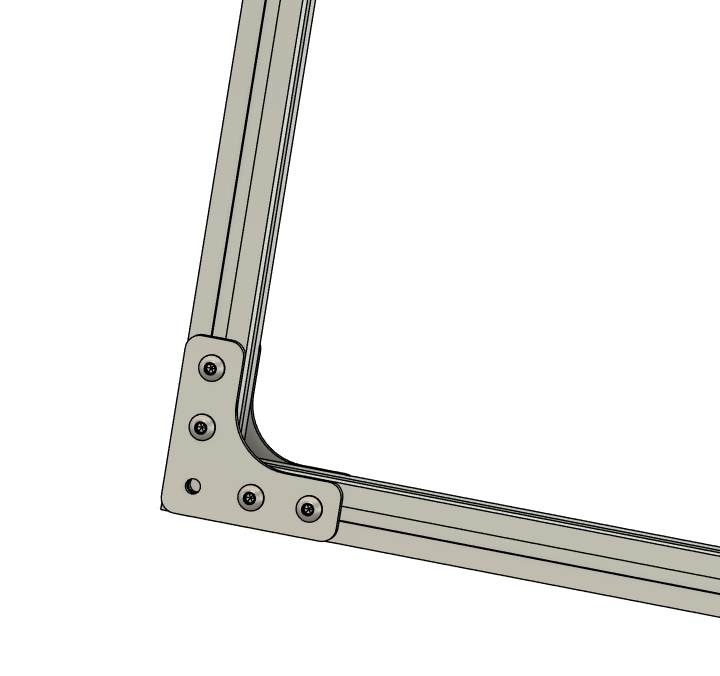

90 Deg Mount

This is the most common way to connect two pieces of 80/20. It creates a strong, simple 90-degree corner, perfect for building the basic frame of a prototype.

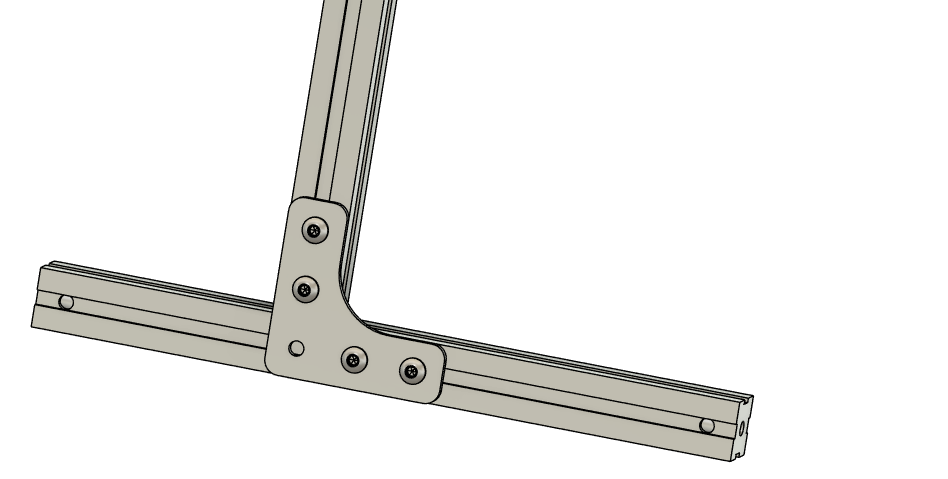

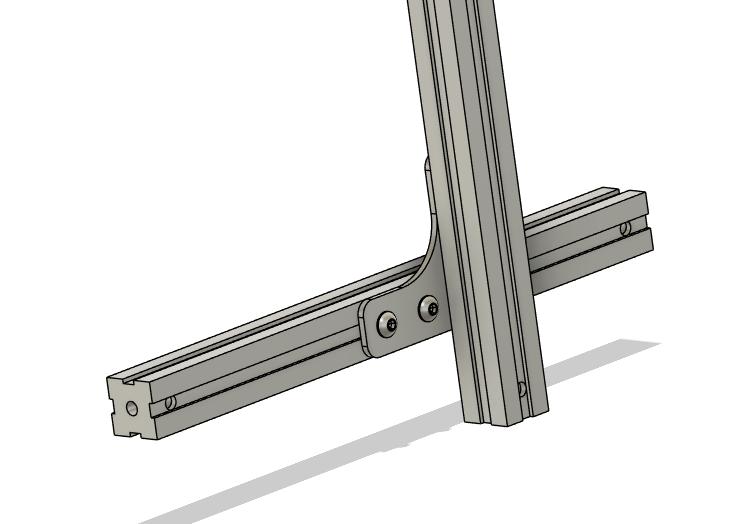

T Mount

Use a T-mount when you need to connect a piece of 80/20 to the middle of another piece, forming a "T" shape. This is useful for adding cross-braces or internal supports to a frame. Because the connection can slide along the main beam, it's also a great way to easily adjust the height of one extrusion.

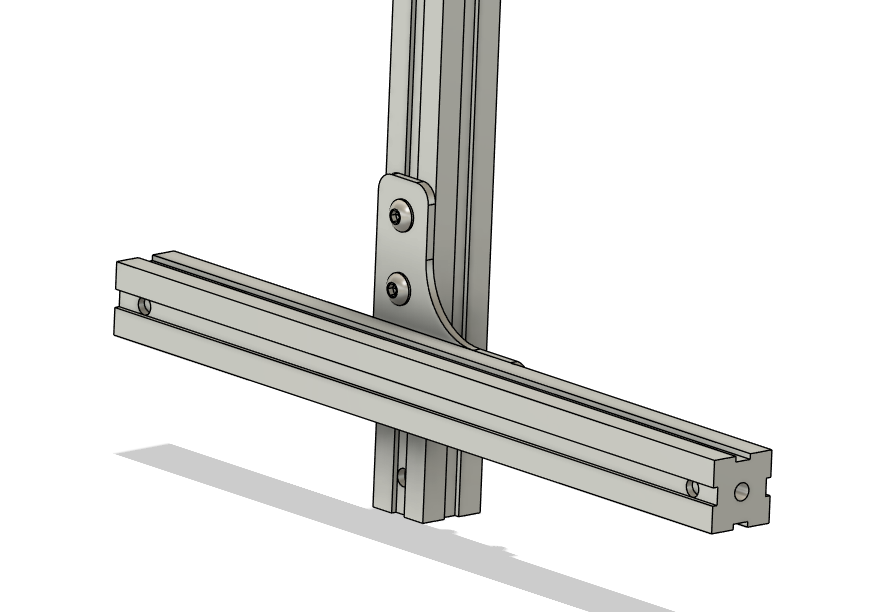

Side Mount

A side mount is used to attach two pieces of 80/20 parallel to each other. This is like the T-mount but allows both extrusions to be adjusted. This is not as strong as the T-mount but is more configurable.

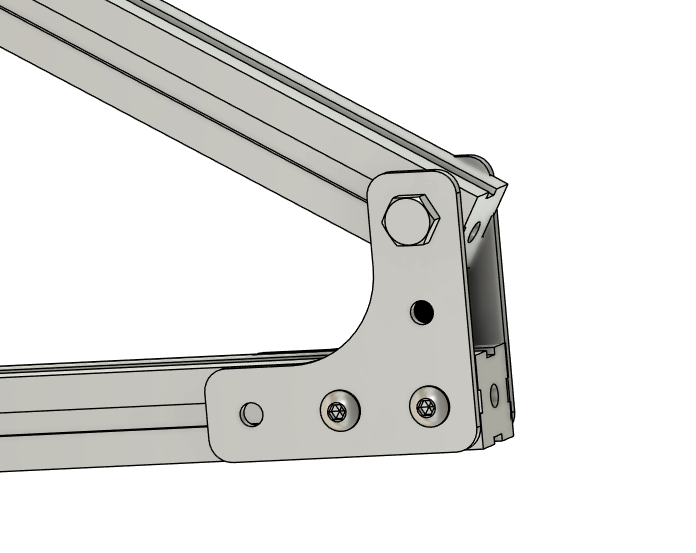

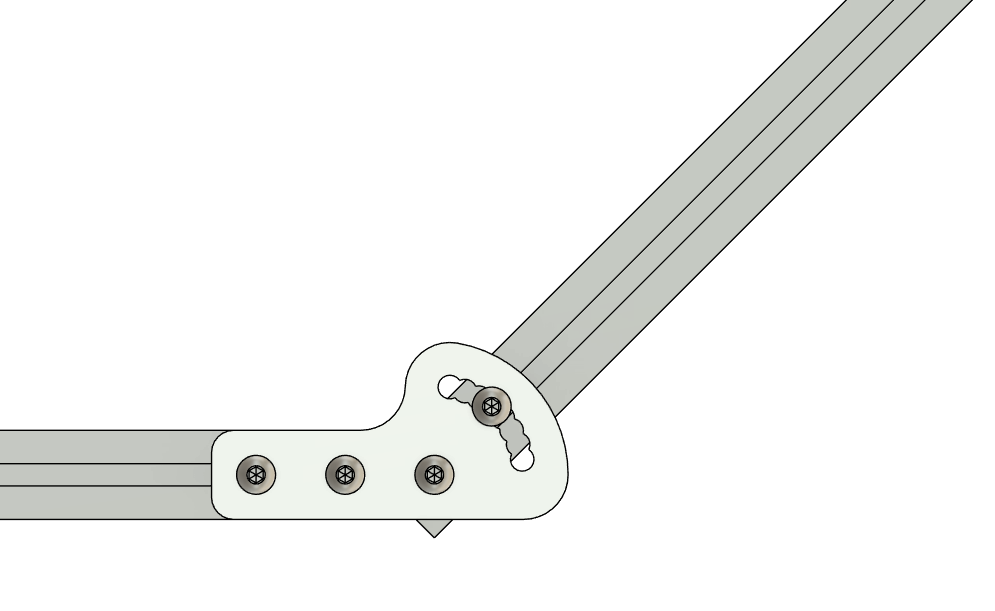

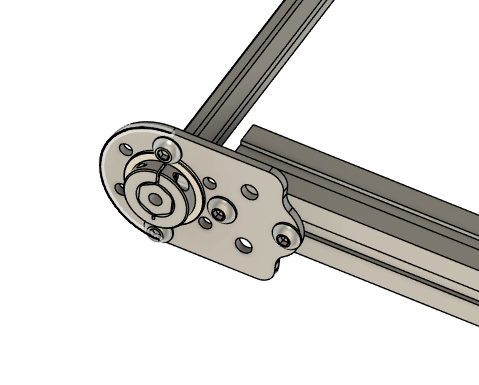

Angle Mount

When you need a connection that isn't 90 degrees, the angle mount is the solution. It allows you to create joints at various angles, which is essential for building more complex shapes like angled shooters or intakes.

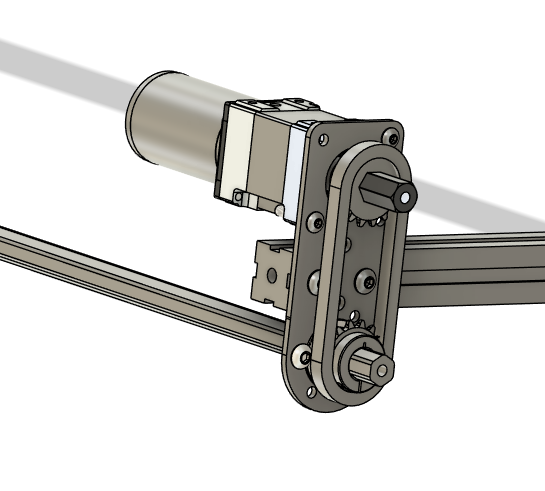

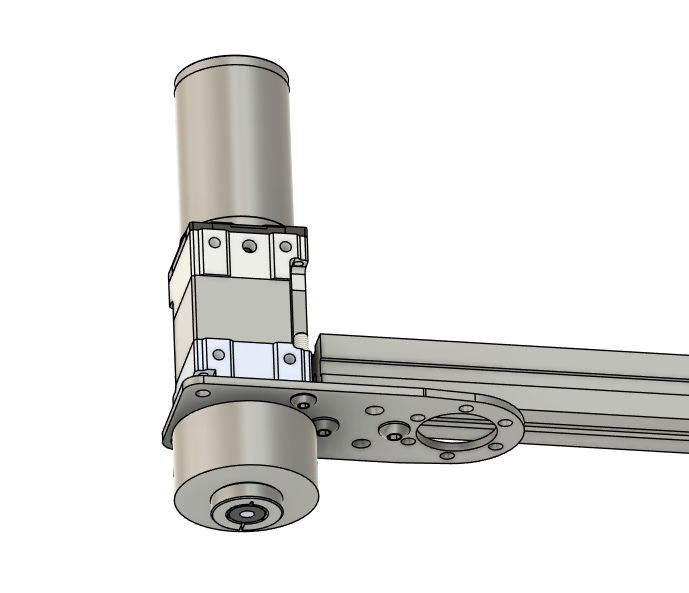

Motor Mount

This mount is good when you need to adjust the position of the motor and want to power a shaft.

This mount is good when you want an end-mounted wheel.

Offset Shaft Mount

This mount is good for end-mounting a shaft.

This mount is good for when you need to adjust the position of a shaft.

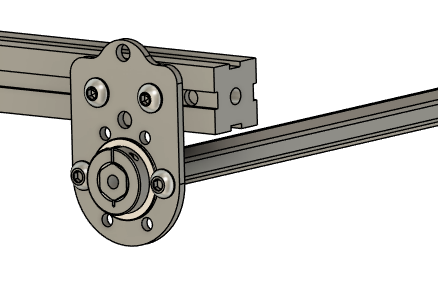

Pivot Mount

A pivot mount is used to create a joint that can rotate. This is perfect for building arms, intakes, or any other mechanism that needs to move.