Prototyping

Prototyping is the process of creating an early model or sample of a product to test concepts, designs, and functionality before full-scale production. It allows teams to identify flaws, refine ideas, and ensure feasibility.

At Argos, we utilized the 8020 system with pre-set gussets to prototype our mechanical designs. This approach enabled us to build and test structures quickly and efficiently.

What is 80/20 and Why Do We Use It?

"80/20" is a brand name that has become a common term for t-slot aluminum extrusion. Think of it like a life-sized Erector Set or K'NEX. It's a system of aluminum beams with slots in them. You can connect these beams together with special fasteners and connectors.

So, why is this useful for building robots?

When we're designing a robot, we need to test our ideas quickly. For example, we might have an idea for an arm that can pick up a game piece. Instead of building the final, competition-ready arm right away (which takes a lot of time and resources), we can build a quick version out of 80/20.

Here's why 80/20 is great for this "prototyping" phase:

- It's Fast and Easy: You don't need to be a welding expert to put it together. If you can use a wrench, you can build with 80/20. This means we can build our test designs in hours, not days.

- It's Adjustable: Is the arm too long? Is a motor in the wrong place? No problem. We can easily loosen the connectors, make adjustments, and tighten them back up. This flexibility is crucial when we're trying to figure out the best design.

- It's Reusable: Once we're done with a prototype, we can take it apart and use the pieces for the next idea. This saves material and money.

Because of these advantages, we use 80/20 to test how we're going to move game pieces and how different mechanisms will work. It helps us learn what works and what doesn't before we commit to a final design for the competition robot.

Standard Parts

8020 Extrusion

Use: Main Structurer

Standard lengths = 18in, 12in

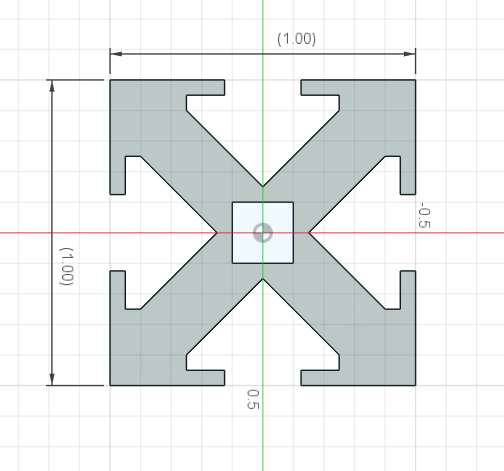

Single T-Nut

Use: Connecting parts to the 80/20 extrusion.

A T-Nut is a special kind of nut that slides into the T-shaped slots of the 80/20 beams. You can slide it to any position along the beam. To connect another part, you put a bolt through that part and screw it into the T-Nut. This clamps the part to the 80/20 beam. They are essential for connecting almost anything to your frame.

Double T-Nut

Use: Creating stronger connections between parts and the 80/20 extrusion.

A Double T-Nut is essentially two T-Nuts fused together. It works the same way as a single T-Nut but provides a stronger connection because it distributes the load over a larger area and uses two bolts.

When to use a Double vs. Single T-Nut:

- Use a Single T-Nut for lighter parts or when you need to make quick adjustments.

- Use a Double T-Nut for heavier components, structural connections, or anywhere you need extra strength and rigidity to prevent parts from twisting or shifting.

1/4-20 Bolt

Use: Connecting Parts Standard lengths = 5/8

This is the standard bolt we use with the T-Nuts. The "1/4" means the bolt is 1/4 inch in diameter, and the "20" means there are 20 threads per inch. You'll use these for almost all connections to the 80/20 frame.

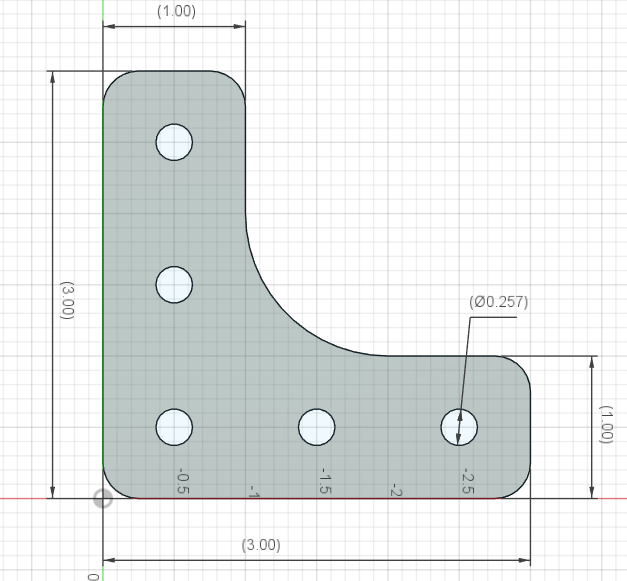

L-Gussets

Use: Connecting two pieces of 80/20 at a 90-degree angle.

L-Gussets are simple, strong brackets used to create right-angle connections. You place the gusset on the outside of the corner and use T-Nuts and bolts to secure it to each piece of the 80/20. They are a quick and easy way to build a square frame.

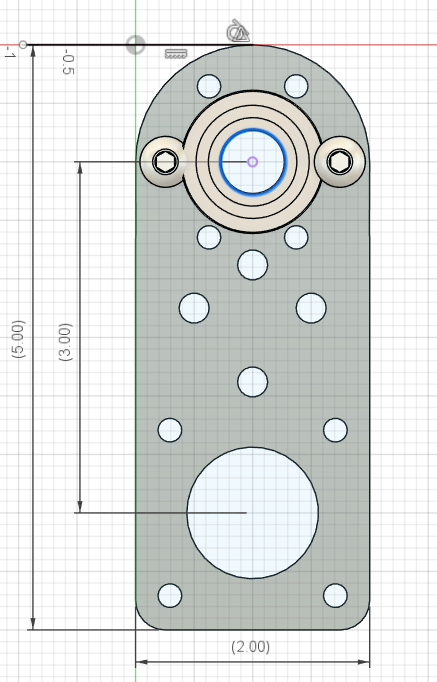

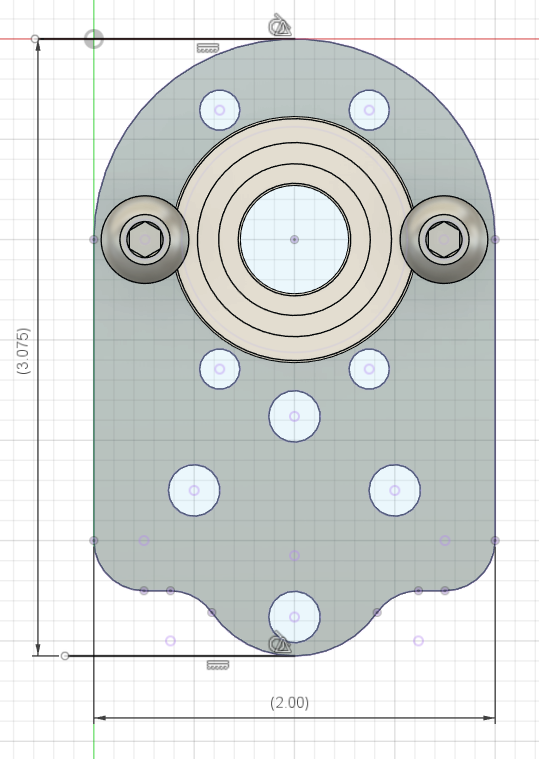

Motor Bracket

Use: Mounting a motor and shaft to the 80/20 frame.

This bracket allows you to mount a motor and a shaft, and connect them together with a 3-inch chain. It's great for turning wheels on your prototypes.

Offset Shaft Mount

Use: Holding a shaft to 80/20 that doesn't need to be powered from that side.

This bracket mounts to the 80/20 frame and is great for holding a shaft when you do not need to power it from that side. Good for pivots or pairing with motor brackets.

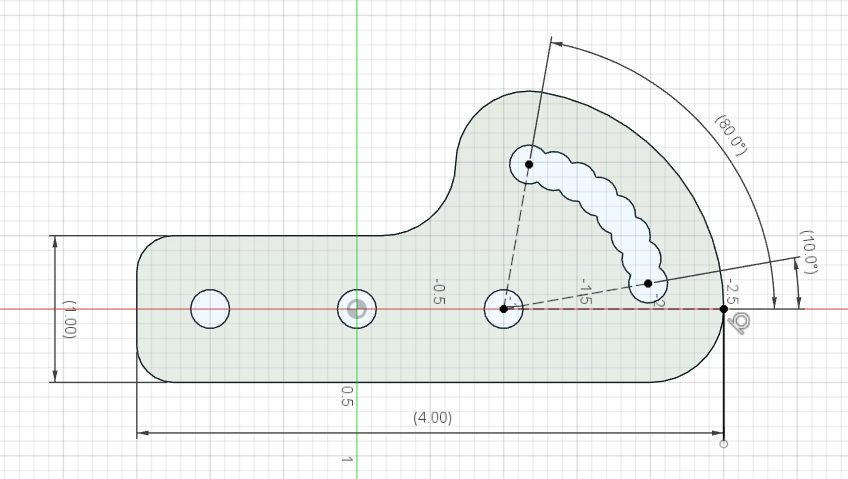

Angle Gusset

Use: Holding 80/20 at set angles from 10-80 degrees.

Each hole in the gusset increases the angle by 10 degrees.